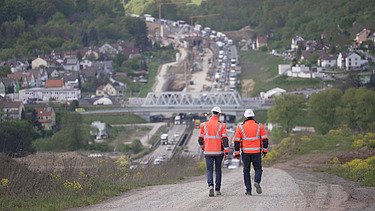

Joint success: How STRABAG and ZÜBLIN are realizing the Enztal crossing

Anyone who has ever traveled on the A8 between Karlsruhe and Stuttgart will be familiar with the bottleneck near Pforzheim. The road narrows here before you drive down and up the Enztal (Enz valley). In order to eliminate this chronic bottleneck, the 4.8-kilometre section of freeway will be widened to three lanes in each direction by 2026 as part of the Enztal crossing project. As an additional 1.1 million cubic meters of soil will have to be moved, this is a multifaceted project with very special challenges. Tim and Johannes, the project managers responsible, explain here how these are being mastered.

What are your respective tasks on the Enz valley crossing?

Tim: I am responsible for the project as overall project manager.

Johannes: My tasks are project management in the field of civil engineering and deputy project management.

Which specific challenges does the project entail and what makes it special?

Tim: Being able to bring together and manage the three group units involved at STRABAG and ZÜBLIN, traffic route construction, civil engineering and specialist foundation engineering, and to make optimum use of their respective strengths is a great experience.

Johannes: The interaction is special because it is a split construction site and not a consortium. This requires a particularly high level of communication in order to keep everyone involved optimally informed at all times. At the same time, we achieve a high level of cost and performance awareness, which benefits the entire project.

Tim: We achieve this through joint planning from the outset and open interaction with each other. Although each unit finds individual solutions for its respective area, this is always done for the common success of the project: everyone trusts each other and works together.

With this in mind, what skills and expertise have been most important for the success of the project so far?

Tim: Our high level of expertise in value stream and material flow management is very important for a project of this size. Specialist knowledge from all areas involved is also essential. In addition, the aforementioned issue of communication channels to keep everyone involved informed at all times. This also includes the fact that we have a paperless construction site; all communication is digital, including with the client.

Johannes: In addition to the technical expertise, the joint work preparation of all those involved is important, so that we approach each other without reservation. The use of LEAN methods on the construction site and the effectiveness of the traffic route construction and specialist civil engineering units in the area of machine technology also ensure that the project runs successfully.

Do you have a personal project highlight?

Johannes: There are many! The main ones are the extensive preparations for the full road closures for the bridge demolition and excavation as well as the large-scale concreting of the superstructure of the bridge over the Enz, which took a total of 36 hours.

Tim: In addition to the great team and the engineering structures, for me it is the intelligently organized mass management of the overall project. I'm also pleased to be able to use all kinds of expertise from my colleagues in the specialist civil engineering department.

What sustainability aspects are being taken into account for the Enztal crossing?

Tim: Very many and comprehensive. One important point is the handling of the soil masses, which was already taken into account in the calculation. This means that we have virtually no disposal of raw materials such as rock, demolition material, old asphalt and old gravel, but can reuse them in the interests of sustainability. As well as benefiting the environment, we also save on material and transport costs.

Johannes: In addition, there are optimized transport routes and noise and dust protection measures for local residents. Conserving resources and reuse - for example through mineral encapsulation of installed pipelines - are important steps towards circular construction. Thanks to our measures, the construction site for the Enztal crossing was pre-certified as a sustainable construction site by the German Sustainable Building Council (DGNB), the first such certification in the field of transportation route construction in Germany.

More generally, what does Work On Progress mean to you?

Johannes: For me, it means that we don't watch and wait, but develop, lead and shape. A future that combines progress and sustainability. This is where the general social challenges are combined with the Group's goals.

Tim: Absolutely! In addition, we have to look ahead every day, recognize improvements and weaknesses and act accordingly. In short: to become better and better at what we do and to translate our diverse skills into innovative and sustainable solutions.

Are you ready for your personal journey at STRABAG?

You can find our vacancies here